News Letter

Sign Up & get 33% off your first order

Enter your preferred name & e-mail to subscribe

A solenoid valve is an electro magnetically controlled mechanical valve used for the ON/OFF (open/closed) or diverting control of liquid or gas media. Solenoid valves are available with a number of port configurations.  The most common solenoid valve is a 2/2 way or 2 port 2 position solenoid valves with 1 inlet port and 1 outlet port for simple ON/OFF or Open/Closed media flow control.

The most common solenoid valve is a 2/2 way or 2 port 2 position solenoid valves with 1 inlet port and 1 outlet port for simple ON/OFF or Open/Closed media flow control.

The picture on the left shows a standard general purpose assisted lift brass normally closed solenoid valve, the BSP female inlet and outlet ports are either side of the main valve body with the electrical solenoid (black electromagnet) on the top. A 2/2 way Normally Open solenoid valve works opposite way around i.e. stays open, uses electrical power to close. Port sizes typically 3/8 thread through to 2" thread, pressures typically 0 to 10 Bar.

Mounted above the solenoid valve is the solenoid coil (electro magnet) which are usually marked with the rated voltage, manufacturer's name and CE marking for use within the European community, ED and power consumption. This electro magnet sometimes referred to as the coil, solenoid or bobine. When this coil or solenoid is energised (electrical power applied) is generating a

for use within the European community, ED and power consumption. This electro magnet sometimes referred to as the coil, solenoid or bobine. When this coil or solenoid is energised (electrical power applied) is generating a  magnetic field which in turn lifts an internal armature (plunger) inside the valve core tube. (The core tube is the tube where the solenoid coil fits onto - see picture on the right). The picture on the left shows how this magnetic force is used to open the solenoid valve, you can see when electrical power is applied the armature / plunger has lifted with the attached diaphragm allowing flow through the solenoid valve. There are various types of solenoid valve, the one shown here is an assisted lift also known as a hung diaphragm solenoid valve, there are also servo / pressure assisted versions and direct acting versions. Helpful hint: Assisted Lift or hung diaphragm solenoid valves are typically manufactured with the solenoid coil mounted centrally over the solenoid valve body. Typical applications: water, air, light oil, vacuum, closed loop systems, gravity fed and low pressure systems, spray systems or where pressure differential is unknown and good flow is required.

magnetic field which in turn lifts an internal armature (plunger) inside the valve core tube. (The core tube is the tube where the solenoid coil fits onto - see picture on the right). The picture on the left shows how this magnetic force is used to open the solenoid valve, you can see when electrical power is applied the armature / plunger has lifted with the attached diaphragm allowing flow through the solenoid valve. There are various types of solenoid valve, the one shown here is an assisted lift also known as a hung diaphragm solenoid valve, there are also servo / pressure assisted versions and direct acting versions. Helpful hint: Assisted Lift or hung diaphragm solenoid valves are typically manufactured with the solenoid coil mounted centrally over the solenoid valve body. Typical applications: water, air, light oil, vacuum, closed loop systems, gravity fed and low pressure systems, spray systems or where pressure differential is unknown and good flow is required.

The picture on the left shows the design characteristics of a servo assisted normally closed (pressure assisted) solenoid valve, (normally open version works opposite way around i.e. stays open uses electrical power to close). The armature is not connected to the diaphragm but instead is used to control an internal pilot or servo circuit which in turn controls the media pressure  above the main seal (diaphragm or piston) so the media pressure difference is used to move the diaphragm or piston to open and close the solenoid valve. Typically, this servo pilot assisted solenoid valves are less expensive than assisted lift solenoid valves, but care must be taken to ensure the minimum pressure difference between the inlet and outlet pressure is observed so that the solenoid valve can function correctly, typically 0.5 bar pressure difference required (ideal for open to atmosphere and high pressure systems). The picture on the right shows a standard general purpose servo / pressure assisted solenoid valve with the inlet port in clear view and the outlet port under the coil. Helpful hint: Pressure or servo assisted solenoid valves are typically manufactured with the solenoid coil mounted over the outlet port of the solenoid valve body. Port sizes typically 3/8 thread to 3" thread, pressures typically 0.5 to 10 bar for diaphragm solenoid valves and over 200 bar for more robustly designed piston solenoid valves.

above the main seal (diaphragm or piston) so the media pressure difference is used to move the diaphragm or piston to open and close the solenoid valve. Typically, this servo pilot assisted solenoid valves are less expensive than assisted lift solenoid valves, but care must be taken to ensure the minimum pressure difference between the inlet and outlet pressure is observed so that the solenoid valve can function correctly, typically 0.5 bar pressure difference required (ideal for open to atmosphere and high pressure systems). The picture on the right shows a standard general purpose servo / pressure assisted solenoid valve with the inlet port in clear view and the outlet port under the coil. Helpful hint: Pressure or servo assisted solenoid valves are typically manufactured with the solenoid coil mounted over the outlet port of the solenoid valve body. Port sizes typically 3/8 thread to 3" thread, pressures typically 0.5 to 10 bar for diaphragm solenoid valves and over 200 bar for more robustly designed piston solenoid valves.

Her e we can see a miniature 2 way direct acting solenoid valve. The schematic on the left shows the armature is directly responsible for controlling the ON/OFF flow of the media, there is no diaphragm used. These compact (miniature) solenoid valves are utilised for the precise and reliable control and typically will work at higher pressures than diaphragm type solenoid valves but have the disadvantage of reduced flow. Typical applications: High pressure, dosing, water, light oil, vacuum,medical equipment, analytical instrumentation, industrial spaying systems and highly integrated automation systems.

e we can see a miniature 2 way direct acting solenoid valve. The schematic on the left shows the armature is directly responsible for controlling the ON/OFF flow of the media, there is no diaphragm used. These compact (miniature) solenoid valves are utilised for the precise and reliable control and typically will work at higher pressures than diaphragm type solenoid valves but have the disadvantage of reduced flow. Typical applications: High pressure, dosing, water, light oil, vacuum,medical equipment, analytical instrumentation, industrial spaying systems and highly integrated automation systems.

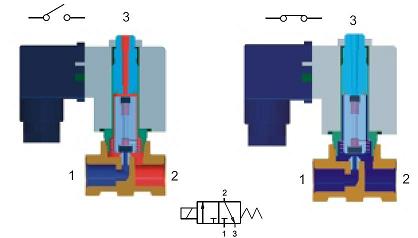

Here we have a miniature 3/2 way (3 ports with 2 positions ON/OFF) solenoid valve used for diverting flow of media.  Looking at the schematic on the right hand side of a normally closed 3/2 solenoid valve with electrical power removed the inlet pressure port 1 is closed but flow is allowed from port 2 to exhaust to port 3. When electrical power is applied the pressure inlet port 1 is open allowing flow through to port 2, however port 3 is closed. (In normally open form port 1 is open to port 2 with port 3 closed and when energised port 1 is closed allowing flow from port 2 to exhaust through port 3).

Looking at the schematic on the right hand side of a normally closed 3/2 solenoid valve with electrical power removed the inlet pressure port 1 is closed but flow is allowed from port 2 to exhaust to port 3. When electrical power is applied the pressure inlet port 1 is open allowing flow through to port 2, however port 3 is closed. (In normally open form port 1 is open to port 2 with port 3 closed and when energised port 1 is closed allowing flow from port 2 to exhaust through port 3).

There is however a third option called universal function, basically the option is the same but the flow direction is universal i.e. in any direction. This type of solenoid valve has compact design but typically limited flow due to such small orifice sizes usually between 0.5 to 3.0mm) thus limiting flow.

Typical applications:pneumatic valve actuator control, pneumatic cylinder control, analytical, diesel veg oil conversion systems and pilot valve control.

Here on the right hand side is a typical 3 way universal solenoid valve. These have the same characteristics as the

A solenoid valve orifice is the diameter of the internal sealing seat is typically measured as the main reference for expected flow being the narrowest point within the solenoid valve limiting flow.

Solenoid valves come in a range of sizes, typically as above from 1/8 port through to 3" port or flanged PN16

Solenoid valves come in a range of sizes, typically as above from 1/8 port through to 3" port or flanged PN16

Now that you are probably more confused than before I would suggest you use a valve selection wizard to narrow your serch down based on the information you have at hand, even if you only have limited information like size and media this will reduce the list by over 90%, and show cheapest first. Goto www.solenoid-valve.world you will see the valve wizard on the right hand side.

A catalouge of articles covering all aspects of solenoid valves

Enter your preferred name & e-mail to subscribe