News Letter

Sign Up & get 33% off your first order

Enter your preferred name & e-mail to subscribe

Water hammer is the pipe banging thumping, pipe clanking and pipe rattling caused by water hammer shock waves that usually start with a loud bang followed by several "echoes" or reducing pressure oscillations.

Water hammer is generated by pressure shock waves caused by sudden changes of water (fluid) flow from sudden pump start up or control valves opening or closing and in some instances the pressure wave can be three times higher than the normal working pressure of the system. Most domestic water systems are regulated down to 2 or 3 bar, so pressure waves can exceed 9 bar, probably enough to damage pipes, pressure vessels (enclosed tanks) and loosen pipes from their mounting brackets.

For example water weighs 1kg per litre (1 gram per cubic centimetre) so if there are sudden changes in flow the weight of water (kinetic energy) travelling along a pipe can be huge and grows expectationally according to pipeline diameter and length.

Buy water hammer arrestors Online.

1. The inverted air pocket water hammer arrestor.

1. The inverted air pocket water hammer arrestor.Basic anti water hammer device, simple by design, no moving parts, cheap and easy to make. Works on the principle that air being 25 times lighter than water will be trapped in a vertical vessel and act as a shock absorber. Water in the pipe below the air pocket will push against the trapped compressed air, the higher the water pressure the smaller and more compressed the air pocket becomes and visa versa thus absorbing water shock waves.

Problems: air dissolves in water, air cannot be replaced without removing device, device must be vertical.

2. The sliding water hammer arrestor.

2. The sliding water hammer arrestor.Traditional cylinder type water hammer arrestor or anti water hammer valve makes use of installed piston between air pocket and water to absorb water hammer affect. Air is trapped behind piston and piston can move backward or foreword according to water pressure against the trapped air pressure. Can be mounted vertically or horizontally not ideally suited to be mounted upside down as debris in water will significantly reduce service life due to wear and damage to piston seals. Problems: manufactured from copper pipe offering very limited wear resistance and debris will damage dynamic piston seals allowing trapped compressed air to escape, friction between wear surfaces reduce operating efficiency, requires disassembly to replace air.

3. Z Tide High efficiency anti water hammer arrestor series.

3. Z Tide High efficiency anti water hammer arrestor series.The z tide anti water hammer arrestor utilises a strong reinforced elastomer diaphragm to form an air chamber that eliminates water hammer pressure waves, allowing totally friction free pressure balanced movement. Additionally for the larger sizes air chamber pressure is given by an external pressure gauge and all AIT and AIF anti water hammer valves can have the air chamber pressure adjusted via the external Schrader valve (bicycle tyre valve). Can be mounted in any direction, optional Bronze, Ductile Iron or Stainless steel.

As the running water pump electrical supply is switched off the pump will continue to function for a while due to the remaining inertia (spinning) of the pump impellers (pump blades) while they slow down. The water flow and impeller direction are both in the normal direction.

The water pump impeller speed is now very slow in normal direction but the water now flows backwards as the water back pressure (static or head pressure) is able to overcome the now much slower pump impeller blade pumping force. The pump impellers / blades are still running in normal direction but the backward flow of water collides directly with rotating pump blades generating a series of unstable pressures causing friction and collision. The result of which can be heard as water hammer effect. At this instance the pressure inside the pipe escalates and the reverse water flow obstructs the forward rotating pump blades which increases the obstructing forces on the forward rotating pump blades causing the pump to slow down an a faster rate.

Pump rotation continues to drop, at the next instance the reverse water flow causes the pump blades to rotate backward or anticlockwise direction.

Stage One: In order to avoid water hammer effect at Stage one above, a check valve should be installed at the appropriate speed to prevent friction and collision from positive and negative pressures inside the water pipe.

Stage Two: After stage two the reverse flow rate generated will cause the check valve to close completely. When the reversed water flow pushes against the check valve it will generate another impact or pressure shock wave so the water hammer arrestor can absorb unstable pressure from the check valve.

- Noise from a malfunctioning or inadequate water hammer arrestor is low and booming, with continuous sounds and pipe vibration.

- High pitch sound coming from malfunctioning or inadequate check valve, which is similar to that of hitting galvanised pipe with a metal hammer.

- absorbs unstable pressure due to sudden closing of valve and subdues (absorbs) the fluid impact inside the pipe.

- Prevents the backward (reverse) flow of fluid media in a pipe. when pump is switched off, the silent check valve will close fast enough to prevent reverse flow but slowly enough to prevent collision between positive and negative pressures, thus will not make or generate any noise.

- Releases pressure above the pre-set safety limit and water hammering effects caused from water pump shut down upstream.

|

Here on the left is a reference layout for check valve, pressure relief valve and water hammer arrestor in a standard water lift pipeline. When the water lift pump is off, the silent check valve can close and gate at the correct speed. Water hammer arrestor can absorb pressure imposed by back flow. If the pressure is above the safety pre-set limit, the over pressure will be released by the pressure relief valve to ensure normal function and working pressure of water lift pipeline. |

|

If only the check valve is installed (without water hammer arrestor), the sudden backward pressure will be imposed on the check valve gate when the water pump is switched off and the check valve closed. This generates another impact (water hammer) effect. |

|

If an ordinary swing check or in line unrestrained check valve is used, the gate closing will need backward flow when pump is off. The backward flow might hit the pump blades (impellers) and in some serious cases, the blades themselves will be damaged by shearing force and will need replacing immediately.

|

|

In the case of long lift (very high) or very long horizontal water pipe, the check valve should avoid being placed in series if water head (weight of water) is low. 1. When the pump is off, upper check valve still has sudden backward pressure, which will be imposed upon the gate and generates another water hammering impact. 2. The water hammer effect is an unstable pressure wave that transfers back and forth inside the water pipe. It is high probable that another check valve will be reversely pushed open, causing more unstable pressure impacts. In this case a pressure relief valve can be used to release the increased pressure and protect the pipeline. |

Miniature Anti water hammer devices for domestic appliances.

Miniature Anti water hammer devices for domestic appliances.Most anti water hammer devices are designed for industrial and heavy duty, high flow, large bore industrial, food or chemical processing applications where trained engineers utilise specialised tools to deal with technically challenging water hammer pressure waves or from pump fed water systems. However there are applications where users or applications have small bore 15mm, 22mm or 1/2" or 3/4" inch thread water pipe and require a smaller more compact yet reliable water hammer arrestors (anti water hammer device) for domestic (home), hospital water, hotel water or any other mains water pressure (UK pressures are between 3 to 6 bar) applications. The AXT patented angle water hammer arrestor has been designed for this more domestic applications with easy installation, maintenance ensuring a quiet water hammer free tranquil friendly environment free for water flow noise and hammer. The AXT system includes a flow controller to help reduce water flow and excess use and proves an ideal Green, environmentally friendly way to reduce water consumption as well as reducing noise.

| Efficient Water Consumption | |||

| Mains Water Pressure |

Water Consumption per person a day |

Water consumption per year per 4 person house |

Water consumption percentage |

| NO AXT Valve mains water | 140 Litres | 200 m³ | 100% |

| AXT Valve set at 30% flow Reduction | 113 Litres | 162 m³ | 81% |

| AXT valve set at 50% flow Reduction | 99 Litres | 142 m³ | 71% |

|

Installing the AXT miniature domestic anti water hammer valve to the heater inlet pipe can absorb this water hammer effect and noise. However also fitting the AXT compact water hammer arrestor valve to the outlet of the shower heater will reduce hammer generated from the shower hose back pressure. As you can see the AXT valve is ideally designed to fit easily in this application and simply replaces the existing pipe elbow fitting. The integral flow controller is a great environmentally green addition as this water hammer arrestor and allows installers to reduce water consumption. The air chamber pressure can be adjusted via the external Schrader valve using a bicycle tyre pump. |

|

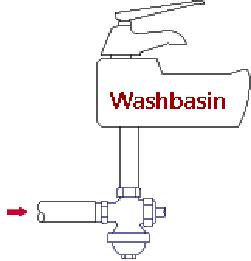

Fast response (fast opening and fast closing) sink, facet and bath taps can cause water hammer effect that will echo and reverberate through the pipework system. The AXT compact anti water hammer valve can reduce this when fitted to the tap water inlet pipe. As you can see the AXT water hammer arrestor is ideally designed to fit easily in this application and simply replaces the original pipe elbow that would have been in the pipework system, or when fitted during installation reduces installation time and pipe fittings. Complete with flow controller this water hammer arrestor and can significantly reduce water consumption. The air chamber pressure can be adjusted via the external Schrader valve using a bicycle tyre pump. |

|

|

Installing the AXT small water hammer arrestor at the water inlet will reduce this water hammer banging and clanking noise. As you can see the AXT valve is designed for this application and fits easily in place of the existing pipe elbow. The integral flow controller is a great environmentally green addition as this water hammer arrestor and allows installers to reduce water consumption. The air chamber pressure can be adjusted or topped up using the external Schrader valve using a bicycle tyre pump. |

A catalouge of articles covering all aspects of solenoid valves

Enter your preferred name & e-mail to subscribe