News Letter

Sign Up & get 33% off your first order

Enter your preferred name & e-mail to subscribe

stable pre-set upstream or back pressure regardless of downstream flow demand. This particular RFT (Threaded 1/2", 3/4", 1", 11/4", 11/2 or 2" BSP or NPT) or RFF (Flanged PN16 DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100 or DN150) direct acting pressure sustaining valve series do not reply on pressure differences to operate as the pressure balanced piston is directly linked to the internal spring and adjustment screw.

stable pre-set upstream or back pressure regardless of downstream flow demand. This particular RFT (Threaded 1/2", 3/4", 1", 11/4", 11/2 or 2" BSP or NPT) or RFF (Flanged PN16 DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100 or DN150) direct acting pressure sustaining valve series do not reply on pressure differences to operate as the pressure balanced piston is directly linked to the internal spring and adjustment screw.

Pressure sustaining valves accurately sustain and automatically maintain these constant pre-set back pressure (upstream pressures) to prevent sudden downstream demands or leaks reducing the upstream system pressure below minimum safe limits. In this way a pressure sustaining valve protects and ensures all all other upstream processing systems have sufficient water supply, which in turn saves downtime and repair costs. The sustained upstream or back pressure is displayed on the pressure gauge mounted on the top of the pressure sustaining valve.

Typical sustained back pressure valves are available with a range of adjustable pressure settings such 1 to 6 bar, 4 to 10 bar or 8 to 13 bar and can be adjusted within these pre-set parameters via the adjustment screw found at the base of the pressure sustaining valve. It is worth noting that most competent pressure sustaining valve manufacturers will pressure test every pressure sustaining valve prior to shipment, therefore customers can request the set pressure when ordering to avoid pressure setting problems after installation into dry systems.

Choosing the correct pressure adjustment range is critical, for example 1 to 6 bar pressure sustaining will use a softer spring to a 8 to 13 bar rated pressure sustaining valve. It is very important that the correct valve pressure range / spring rating is used in relation to the pressure range to be controlled as this spring must be under compression with additional room to compress and expand. If the wrong spring is used of if a spring is damaged or broken the pressure sustaining valve will not be able to accurately maintain a stable back pressure. The worst case scenario is that the wrong pressure range is chosen, installed or supplied so the system pressure could easily drop below the minimum pre-set back pressure causing catastrophic damage in cost and production down time. Always check the valve pressure ratings are in excess (both minimum and maximum) of those required by the system design, keep the equipment clean during installation and flush through with chemically compatible cleaning agents. Do not use any chemicals that could damage the materials of construction, paying careful attention to any chemicals that might need diluting as some less experienced engineers may not realise that dilution is required prior to system application rather than just adding water later thus allowing the potential for corrosion due to undiluted chemicals of pools of concentrated chemicals being left in the system prior to fresh water being run through the system.

Pressure sustaining valves can be manufactured in brass, bronze, cast iron, ductile iron or stainless steel. 316 Stainless steel has always been seen as the expensive option but recent material increases have moved brass and bronze prices up closer to stainless steel making stainless steel a sensible, cost effective, wear and corrosion resist and solution. Keeping in mind that a pressure sustaining valve is designed to maintain system back pressure to protect upstream systems, making small installation cost savings could prove a highly expensive mistake in later years.

Temperature Range: -15°C to +80°C.

Valve body test Pressure: 21 Bar.

Pressure Gauge indicates the sustained back pressure.

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

For systems requiring different pressures installing a back pressure or pressure sustaining valve can maintain the required pre-set pressure and in combination of pressure reducing valves for maintaining safe system pressures within design parameters. |

|

|

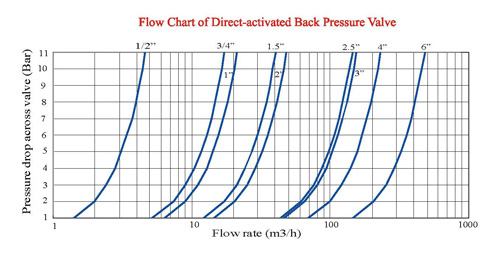

By installing a pressure sustaining / back pressure valve accurately stabilises system pressure whilst allowing high flow. |

A catalouge of articles covering all aspects of solenoid valves

Enter your preferred name & e-mail to subscribe