News Letter

Sign Up & get 33% off your first order

Enter your preferred name & e-mail to subscribe

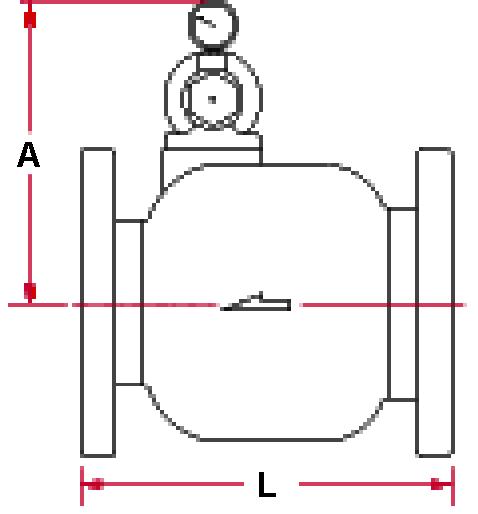

BFR Pressure Reducing Valve (PRV) is designed to reduce, protect and maintain a pre-set reduced outlet pressure regardless of inlet pressure changes or downstream flow demands. Pilot operated pressure reducing valves utilise the pressure differential across the valve (difference between inlet and outlet pressures) via an external fluid control circuit and controller that utilises the media pressure differences to mechanically move the internal main valve piston or diaphragm, which is unlike a direct acting pressure reducing valve where the mechanics of the controller are directly linked to the pressure controlling piston. The advantages of external pilot control are that the controller will remain the same across a full range of pressure reducing valve materials such as bronze, 304 or 316 stainless steel and even epoxy coated ductile iron from flanged port sizes DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250, DN300, DN350, DN400, DN450 and even DN500 and beyond.

System pressures can fluctuate considerably due to sudden stops in demand, pump start up or shut down and other control valve actuation anywhere upstream of the pressure reducing valve, or system pressures may need to be increased to supply an ever increasing demand for water further downstream. The pressure reducing valve can solve most of these over pressure problems and is designed to automatically reduce inlet pressure down to a pre-set outlet or downstream pressure with outlet pressure displayed externally via a pressure gauge.

For example the BFR cylindrical patented high flow compact, strong robust internal piston pressure reducing valve has evolved into an industry leading standard, simple easy to install and maintain high flow compact cylindrical body and simple easy to replace remove or exchange external pressure controller, without fragile external pipework and fittings which are in themselves potential leak points.

Flanged pressure reducing valves are designed to slide in between flanged pipework systems without the need to remove large amounts of heavy downstream pipework and other process systems that you would normally expect to do with threaded systems down to where unions are fitted. Flanged pressure reducing valves with fit directly between mating flanges of the same size (DN in mm i.e. DN100 is 100mm) of the same specification ie PN16, PN10, ANSI 150 or JIS10K etc. The only additional issue is to have enough space between the mating flanges to fit the pressure control valve as too little a space will generate huge headaches for installation engineers whereas if the space between the existing pipework flanges is too big, engineers can simply fill the gap with flange spacers. In an ideal world the space between the pressure reducing flanges should be a perfect match with some adjustment available via pipework elbow flexibility or expanding joints.

Most externally pilot operated pressure reducing valves are designed to reduce water pressure, however as there are usually a range of body materials available there will also typically be a range of sealing materials available from standard NBR to FKM for more challenging liquids, but caution must be given to all materials of construction especially the pressure reducing valve external controller. Most flanged pressure reducing valves are supplied with industry standard PN16 flange, however as the BFR manufacturers are more forward thinking and produce valve castings initially with blank ends, so just about any flange configuration can be quickly machined and supplied from these blank ends according to customer specification such as ANSI150Lb, JIS10K etc. to name but a few.

BFR outlet Adjustable Pressure Ranges: 0.2 to 4 Bar, 2 to 8 Bar or 4 to 12 Bar, with Pressure Gauge displaying the reduced outlet pressure.

Size Ranges: Flange DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250, DN300, DN350, DN400, DN450, DN500 all the way to to DN1400 and beyond.

Valve Materials: Bronze, Ductile Iron, 304 and 316 Stainless Steel

Test Pressure: 21 to 35 Bar depending on body material.

|

|

||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||

|

All pressure reducing valves are 100% pressure, leak and function tested prior to despatch. With a consistent focus and commitment to product quality. The hydraulic testing machine seen on the left locks and seals the valve body into place. Clean water is then pumped at various pressures and flow into the base of the BFR pressure reducing valve and the outlet pressure at the top can be checked from the pressure gauges.

|

|

You can see here that the BFR-D ductile iron epoxy coated pressure reducing valve during the pressure, function and leak test procedure. Inlet pressure and the reduced outlet water pressures are clearly visible by the pressure gauges. As you can see from the picture on the left, the cylindrical main valve body is controlled by a small brass pressure reducing valve controller, which can be removed and easily replaced for shipping or during the installation process. One very helpful aspect of the manufacturing quality control testing process is that the pressure controller can be pre-set according to customer requirements and installed on site without the need for adjustment. |

|

The pressure reducing valve BFR-D inlet out reduced pressure outlet pressures can be seen here on the left. with an inlet pressure of 5 bar the outlet pressure has been adjusted down to 3.2 bar for our UK customer. These pressure pre-set pressure reducing valves where then installed on a water mains system and the contractor was able to commission the system dry. Results of this pressure pre-set service saved our customer £1000's in down time without the need to fill the system with water and make pressure adjustments or remove the valves and send them away for pressure adjustment. The chief engineer was delighted when the system went live as the BFR pressure reducing valves reduced the mains water pressure down to the exact specified pressure.

|

|

BFR800-D DN800 32" inch PN16 water pressure reducing valve designed to reduce water pressure down from 10 bar to a adjustable outlet pressure range of 1 to 6 bar. Also available with 304 BFR800S or 316 BFR800SS stainless steel body with a maximum working pressure of 16 Bar and pressure tested to 35 bar. The BFR800 has an external pressure reducing pilot valve, pressure gauge, needle operating speed control valve and Y strainer filter assembly. The BFR strong internal piston design with U ring seals offering excellent sealing, robust, high flow and long maintenance free service life.

|

A catalouge of articles covering all aspects of solenoid valves

Enter your preferred name & e-mail to subscribe